Flexible batteries, Velcro metal, colorful conductive inks, and more.

Andrew Dent, vice president of library and materials research at Material ConneXion, is like a sommelier. Presiding over the world's largest library of materials, his job is to listen to the requirements of his clients—a list which includes Armani, Chrysler, Calvin Klein, Hermann Miller, Disney, Nike, Toyota, and many, many more—and come up with an innovative material that suits their needs. His level of obsession in this field is such that he makes Apple's Jonathan Ive, a fellow Brit, seem like he's never done his homework.

During Fast Company's Innovation Festival earlier this month, we caught up with Dent during a tour of Material ConneXion's materials library, and asked him to identify a handful of the cutting-edge materials that he thought would be important to designers over the next few years.

Graphene Nanocoating

One hundred times stronger than steel, amazingly light, nearly transparent, and capable of efficient heat and electrical conductivity, graphene has applications in solar power, electronics, biomedicine, and more. But it's a relatively difficult material to work with and mass-manufacture in its purest forms. Graphene nanocoating allows other materials to be coated with the material, giving them most of graphene's best qualities cheaply and efficiently. One possible industrial design use is using graphene nanocoating to help make thinner, lighter, stronger smartphones with better battery life.

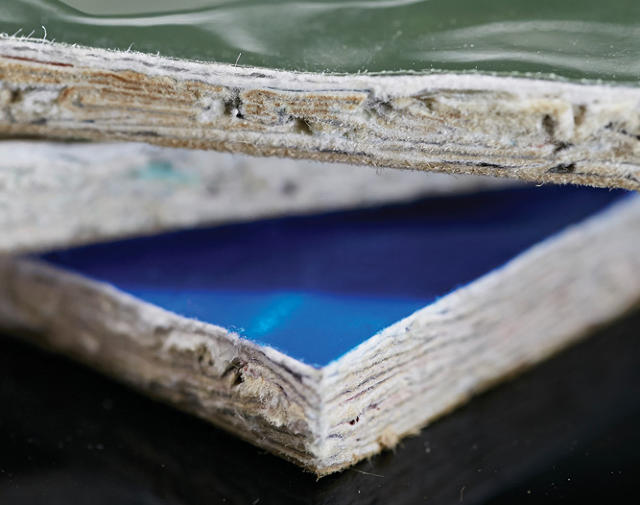

Karta-Pack (Cotton Fiber)

This 100% post-consumer material, which has the feel of cotton but the rigidity of plastic, is made from recycled cotton fibers, sourced from the likes of discarded jeans and T-shirts. In addition to helping recycle millions of articles of clothing per year, Karta-Pack feels fairly luxurious, making it an interesting choice for high-end packaging. Imagine unpackaging a gadget from what feels like rigid cotton. Dent also suggests that furniture designers could end up using Karta-Pack to create molded furniture designs that feel like fabric, even though they're strong enough to support a person's weight.

Colored Conductive Inks

Although we've had inks that can conduct electricity for years now, these inks only come in two colors: silver and carbon. It gives conductive inks an aesthetic, says Dent, that has "no real beauty for non-engineers." A new breakthrough, however, has finally made it possible for conductive inks to come in any color you want. One potential use is in smart clothing and wearables. Imagine a jacket with an attractive design printed on the sleeve that also functioned, when you touched it, as a way of controlling your iPhone.

ReWall Ceiling Tiles

ReWall Ceiling Tiles are made from recycled beverage containers—a mixture of cardboard, plastic bottles, and aluminum—using a method similar to the way oriented strand board, a construction-industry staple, is made. The result is a material that has the same structural integrity as strand board and can be cut and screwed into like wood, but which has much better resistance to moisture, so it can be used as a ceiling tile. It can also be exposed to the elements.

ZrOC

The process of coating most decorative metal items, like your sink or your hubcaps, for improved hardness and scratched resistance is called physical vapor deposition, or PVD. ZrOC is a new coating technique in which a mixture of zirconium, oxygen, and carbon can be deposited on metal, plastic, wood, glass, or textiles. Depending on how those elements are mixed, you can get chrome in any color you choose, as opposed to the stock reflective silver. "It was actually invented for coating kitchen implements, but I can definitely see someone coating a smartphone or a smartwatch in ZrOC soon," says Dent.

Tethonite

3D-printed objects always look and feel inferior to objects made with traditional manufacturing processes and materials. Tethonite is different: It's a 3D-printed ceramic compound that, when fired and cured, looks identical to ceramic made by hand or industrial machines. Not only could Tethonite push the boundaries of the ceramic arts by making increasingly intricate designs possible; it also potentially has wide-ranging consumer applications. "Companies like Apple want to figure out new ways to use ceramics, because it's such an incredible material," says Dent. "It's so hard, subtle, and luminous, but unlike metal, ceramic is also brittle." It breaks, which is why you don't see it in many gadgets (although the Apple Watch Edition recently introduced a high-end ceramic model). Tethonite could let companies like Apple intimately combine the best qualities of metal and ceramics to create resilient new devices.

ThermalTech

A patented lightweight smart fabric made of 100% stainless steel mesh that is coated with a solar selective coating, ThermalTech could be a boon to makers of athletic gear. The fabric excels at absorbing heat in the form of ultraviolet light, then dispersing it throughout the entire material to dissipate. Imagine athletic gear that keeps you as warm as wool without the bulk and you've got an idea on why companies like Nike might be interested in ThermalTech. These companies, says Dent, "have already figured out materials to eliminate odors and sweats. Temperature regulation is the next holy grail."

Paptic

Blurring the line between paper and plastic, Paptic is a new material that is easy to print on, easy to recycle, and perfect for packaging. "It might not change the world," Dent admits, but he thinks we'll soon start seeing it everywhere, because while it feels and looks like paper, it's as strong and tear-proof as plastic.

RE>CRETE

Concrete is a composite that is basically made up of a bunch of junk—mostly sand and gravel—bonded together with cement. RE>CRETE isn't that different, except instead of using sand and gravel, it contains shredded newspaper and junk mail, ground up packing Styrofoam, home electronics wire, credit cards and CDs, salvaged house paint, dryer lint, Portland cement, and fly ash. It's basically construction scale recycling: With RE>CRETE, tomorrow's buildings will be built with today's trash.

Flexible Battery

Imagine wearing an entire suit that was just one big lithium-ion battery. Jenax Inc. Flexible Battery could make that possible. "The difference here is that while normal batteries come in solid pieces, this battery is spun from fibers which make it more flexible," explains Dent. Flexible Batteries can apparently be flexed a couple of thousand times without affecting their performance, making them a perfect choice for tomorrow's smart clothing, e-textiles, wearables, and transforming or flexible gadgets.

Grip Metal

Think Velcro for metal, and you've got a good idea of what Grip Metal can do. It's a patented stamping process that allows two pieces of metal to stick together without being glued, welded, or bolted together. When stuck together, the two pieces become up to three times as strong as they were individually, making it a perfect material for furniture design, manufacturing, and construction.

All of these materials are available now, but they're not yet commonplace. Expect to see them in the months and years ahead. To hear Dent tell it, they are the new stars of the materials science scene.